Equipment introduction

The splitter may effectively eliminate in the lubricating oil,the turbine oil, the refrigerator oil, the transformer oil and themachine oil moisture content and the mechanical impurity, reduces themachine to wear and to lengthen the lubricating oil period ofrevolution; Also may use in to eliminate the light diesel oil or tostop up and so on the breakdown; Or to the heavy oil replaces thelight diesel oil use, reduces the cost.

This type also may separate other two kind of proportions to bedifferent, also mutually does not dissolve in liquid or liquid fewsolid particle.

This type for manual drawing out clinker splitter, operation simple,the demolision is convenient.

Principle of work

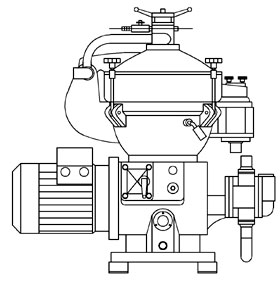

The CGL series splitter mainly by the rotor drum, vertical shaft, the shaft level, the rack, measured the fast installment, thebrake system, the control valve, the oil pump and the electric motorand so on compose.

Separation of materials into question within the drum disc separation zone separation, the use of materials oil, water, the residue of different densities in different centrifugal force was the centrifugal force which is separated from the oil off by the heart to pump output, the proportion of water from the Central mouth thrown off, exports from the sewage discharges, the question Deslagging impurities from the drum Deslagging I ruled out.

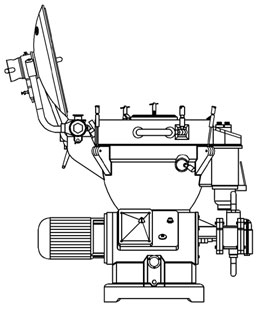

Splitter contours

Installs the notice

1, the installation must have a firm foundation, formation, the machine to prevent the vibration transmission to the surrounding areas, the separator machine with the installation of a shock absorber between Block. Isolation is linked with the hose pipe to be used. 2, the separator should be equipped with the oil heater, heating materials to be separated. 3, separation machine should be equipped with start-up kit, sealing water.

Technical parameters

|

|

|

|

|

|

|

|

L/H |

8500 |

|

Kg/c㎡ |

Kg/c㎡ |

kg |

|

3500 |

≥25 |

≥6 |

290 |

|

6000 |

380 |

|

8500 |

520 |

The various mineral oil separation conditions and the actual throughput recommended Table |

|

|

|

|

|

|

Low-speed machine

Quality Oil |

Medium-speed machine

Oil Purification |

|

|

m㎡/s(50℃) |

m㎡/s(40℃) |

|

13 |

20.5 |

36.2 |

80 |

180 |

380 |

460 |

600 |

100~120 |

65 |

|

|

Kg/m3(20℃) |

|

≤900 |

900~991 |

880~900 |

900 |

|

(℃) |

40 |

60 |

80 |

98 |

|

75 |

Actual throughput with a rated capacity ratio (‰) |

110 |

100 |

60~65 |

45~50 |

35~40 |

20~25 |

50~60 |

25~30 |

80~85 | |